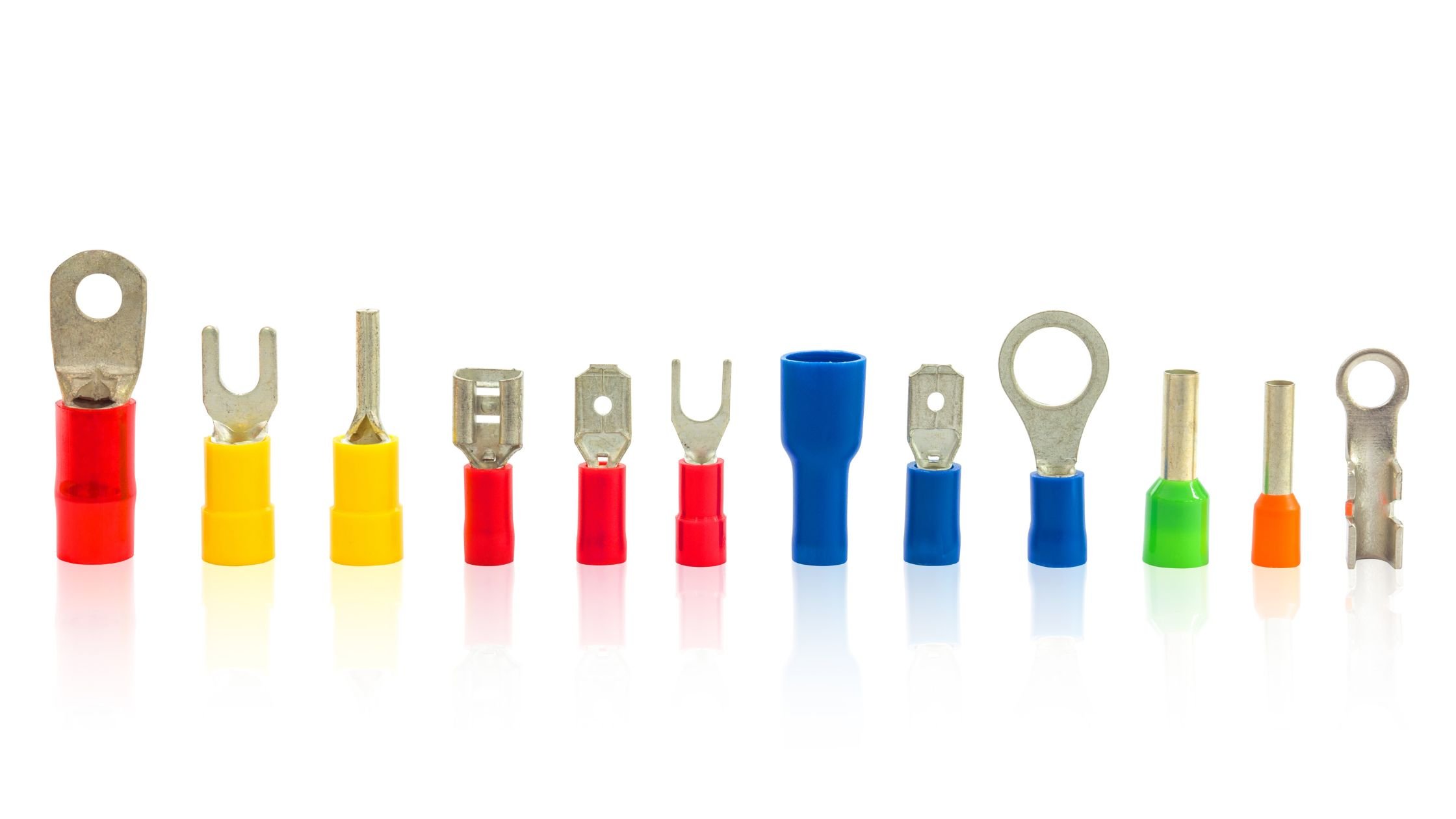

There are a variety of electrical terminals you can choose from when you need to do an electrical wiring project. Using the right one is important not only for your personal safety, but for ensuring a safe electrical connection at the installation point in a facility, on equipment, and for other home or business applications. Since electrical currants and wire sizes vary based on the project, you will need to do some research to find the right one that can handle the electrical load, and protect the wires at its connection point. At Electrical Basics, there are a number of choices from the small and simple electrical connections, to ones that require a strong, sturdy connection for more permanent and hazardous installations.

An electrical component uses terminals to make electrical wire connections. A terminal connection must have solid mechanical contact and good electrical contact to work effectively and to prevent damage to the conductors. An experienced electrician can help you to better understand how to ensure safety when attaching electrical terminals to exposed wires. An electrician would also help you to make a safe electrical connection that can be approved by your local regulatory requirements. With that in mind, let’s take a look at insulated ring or spade electrical terminals to help determine which one you’ll want to use to fit your need:

1.) Insulated Ring Terminals

Insulated ring terminals are used to connect wiring to screws and studs. A variety of ring sizes are available and are designed to fit the requirements of amperage throughput and the wires being used. You’ll need to find the right size of ring terminals to fit the wires you are using. This is determined by the size of the conducting wire and the placement of the screw or bolt. The rings are used to mount the wires, where electrical contact is made on the flat surface of a ring or spade terminal. Using an insulated closed barrel terminal is not only ideal for crimping the wire to the terminal, but this is what encapsulates the connections. The insulation properties in the ring terminal provide a barrier from extreme heat and cold, and protects from dust, debris and corrosion so the wire connection can stand up to use for long periods of time.

2.) Insulated Spade Terminals (also known as ‘fork’ or ‘split ring’)

Insulated spade terminals are also referred in the industry as spade connectors. Spade terminals are used to connect or terminate a single wire while it is connected to a stud or screw type used for an electrical connection. Since the shape of the spade is similar to a fork or spade, it’s shape allows you to quickly set screws in place. There are different characteristics for each type of spade terminals so it’s important to know where and how you plan to use it. You’ll want to use ones that have the proper amperage rating, and use an insulated terminal that will work best for your application and gauge size, which is determined by the type of wire you are using. A spade terminal is easy to use, and is a fast process for connecting electrical wires because the screw or bolt can be left partially screwed in when a terminal is attached or removed.

Since the demands are varied for electrical connections in the many industries that use spade and ring terminals, a variety of sizes is necessary. To find the right size for your project visit:

Next, You’ll need to decide which Terminal Type will work Best

Insulated Vinyl terminals have a wide opening which allows the wires to slide into the barrel easily. Vinyl terminals are made from tinned plated copper body and tinned copper wire support with a PVC (plastic) barrel. An insulation sleeve is used in a closed barrel that will link a wire to an electrical component. Vinyl provides good dielectric strength and supports the wire insulation in the barrel. This is a lower cost option, although the insulation sleeve protects the wires, it does not fully encapsulate the connection.

Insulated Nylon Terminals are insulated with nylon material and offers better performance than vinyl. Nylon terminals are a double crimp style, meaning you will crimp the wire at the bottom and the top which will provide for a better connection. The nylon material is an elastic so they stretch and won’t crack the insulation inside the terminals. It is more flexible than a plastic connector which helps to minimize damage to, or expose the wires when moved, which could lead to electrical failure. Nylon has good dielectric properties, won’t ‘gas out’, and is more resistant to oils and combustible fluids.

Heat Shrink Terminals are commonly used when a complete seal is necessary for protecting against contamination and moisture. To make wire connections using heat shrink terminals you will need to first prepare the wire and insert all of the copper strands so that they fit into the terminal barrel, making sure you have a perfect fit so that the copper wiring is not exposed. You will then crimp the terminal before applying heat. When the wire and crimping are set you’ll need to apply heat from a commercial heat gun or paint peeling gun (hair dryers do not have enough BTU) to heat the terminal. By applying heat, the adhesive material begins to shrink and then melts onto the wire, forming a tight seal by keeping the insulation and wires safely encased. The new seal insulates the wires, makes it air tight, and is resistant to moisture and chemicals. A sealed terminal also acts as a strain relief on the wire connection. You should do a seal strength test by pulling on the wires after sealing to make sure it is secure and the seal is completed.

The advantage to using heat shrink terminals is obvious, the seal prevents the wires from being exposed to damaging corrosive liquids such as salt and fresh water, acid, chemicals, as well as to outdoor elements. Heat shrink terminals are perfect for many automotive and marine applications, industrial applications and even projects around the home.

A Compression Clamp Tool is used for crimping the Connections

Compression clamp tool is used to crimp the terminal to the wire, producing a secure bond. A compression clamp tool is necessary in order to put equal pressure to the crimp area. Before crimping, you must strip the wire no more than 3/8” of the wire end, then insert the exposed wire into the terminal end.

Compression clamps are special crimping pliers made especially to mechanically join connectors of many types and sizes. They are used on a range of wire sizes from 10 to 24. The upper jaw of the clamp has a punch that protrudes and that matches a die on the lower jaw. Once the wire is inserted into the connector, the connector is inserted into the pliers where you will apply force to the handles. The resulting crimp is the pliers piercing the insulated terminal connector into the wire, making a permanent connection. It is important to use a proper crimping tool as it contributes to the integrity and performance of the connection.

To find the right Insulated Ring Terminal or Spade Terminal for your project visit : Electrical Basics or call us at 877-947-8437.