Adhesive back urethane bumpers for appliances and equipment. An extensive selection of bumpers and feet, for the OEM and Do-it-yourself (DIY) markets. These bumpers and feet are meant to help provide stability, clearance, compatible appearance and other desired characteristics to a wide array of appliances, cabinets, housings and other unique equipment applications. Our two-piece feet are furnished in push-pin, screw or rivet style and our broad selection of urethane bumpers with adhesive back come in clear, white and black color selections.

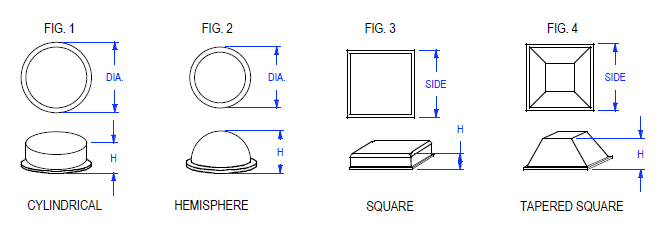

| ITEM NO. | Style | Diameter inches (mm) |

Height inches (mm) |

Color | Adhesive Type |

Bag Qty |

Fig. No. |

| EBBF-05-02-110-CL |  |

.375 (9.5) | .125 (3.18) | Clear | Rubber | 600 | 1 |

| EBBF-05-02-110-BK | .375 (9.5) | .125 (3.18) | Black | Rubber | 600 | 1 | |

| EBBF-05-02-114-CL | .375 (9.5) | .190 (4.8) | Clear | Acrylic | 500 | 1 | |

| EBBF-05-02-114-BK | .375 (9.5) | .190 (4.8) | Black | Acrylic | 500 | 1 | |

| EBBF-05-02-115-CL | .500 (12.7) | .125 (3.18) | Clear | Acrylic | 500 | 1 | |

| EBBF-05-02-115-BK | .500 (12.7) | .125 (3.18) | Black | Acrylic | 500 | 1 | |

| EBBF-05-02-118-WT | .500 (12.7) | .140 (3.6) | White | Acrylic | 500 | 1 | |

| EBBF-05-02-118-CL | .500 (12.7) | .140 (3.6) | Clear | Acrylic | 500 | 1 | |

| EBBF-05-02-118-BK | .500 (12.7) | .140 (3.6) | Black | Acrylic | 500 | 1 | |

| EBBF-05-02-120-WT | .500 (12.7) | .250 (6.4) | White | Acrylic | 500 | 1 | |

| EBBF-05-02-120-CL | .500 (12.7) | .250 (6.4) | Clear | Acrylic | 500 | 1 | |

| EBBF-05-02-120-BK | .500 (12.7) | .250 (6.4) | Black | Acrylic | 500 | 1 | |

| EBBF-05-02-130-CL | .650 (16.5) | .400 (10) | Clear | Acrylic | 250 | 1 | |

| EBBF-05-02-130-BK | .650 (16.5) | .400 (10) | Black | Acrylic | 250 | 1 | |

| EBBF-05-02-138-CL | .750 (19) | .160 (4) | Clear | Rubber | 490 | 1 | |

| EBBF-05-02-138-BK | .750 (19) | .160 (4) | Black | Rubber | 490 | 1 | |

|

-

|

|||||||

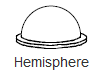

| EBBF-05-02-065-CL |  |

.250 (6.4) | .065 (1.6) | Clear | Rubber | 484 | 2 |

| EBBF-05-02-065-BK | .250 (6.4) | .065 (1.6) | Black | Rubber | 484 | 2 | |

| EBBF-05-02-108-CL | .312 (7.9) | .085 (2.2) | Clear | Rubber | 450 | 2 | |

| EBBF-05-02-108-BK | .312 (7.9) | .085 (2.2) | Black | Acrylic | 450 | 2 | |

| EBBF-05-02-109-CL | .335 (8.5) | .085 (2.2) | Clear | Rubber | 450 | 2 | |

| EBBF-05-02-109-BK | .335 (8.5) | .085 (2.2) | Black | Rubber | 450 | 2 | |

| EBBF-05-02-111-CL | .375 (9.5) | .085 (2.2) | Clear | Acrylic | 750 | 2 | |

| EBBF-05-02-111-BK | .375 (9.5) | .085 (2.2) | Black | Acrylic | 750 | 2 | |

| EBBF-05-02-128-CL | .375 (9.5) | 150 (3.8) | Clear | Acrylic | 500 | 2 | |

| EBBF-05-02-128-BK | .375 (9.5) | 150 (3.8) | Black | Acrylic | 500 | 2 | |

| EBBF-05-02-208-WT | .437 (11.1) | .200 (5.1) | White | Rubber | 500 | 2 | |

| EBBF-05-02-208-CL | .437 (11.1) | .200 (5.1) | Clear | Rubber | 500 | 2 | |

| EBBF-05-02-208-BK | .437 (11.1) | .200 (5.1) | Black | Rubber | 500 | 2 | |

|

-

|

|||||||

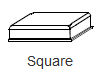

| EBBF-05-02-408-CL |  |

.500 (12.7) | .120 (3.1) | Clear | Rubber | 500 | 3 |

| EBBF-05-02-408-BK | .500 (12.7) | .120 (3.1) | Black | Rubber | 500 | 3 | |

|

-

|

|||||||

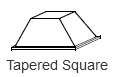

| EBBF-05-02-308-CL |  |

400 (10.2) | .100 (2.5) | Clear | Acrylic | 484 | 4 |

| EBBF-05-02-308-BK | 400 (10.2) | .100 (2.5) | Black | Rubber | 484 | 4 | |

| EBBF-05-02-418-CL | .500 (12.7) | .230 (5.8) | Clear | Acrylic | 500 | 4 | |

| EBBF-05-02-418-BK | .500 (12.7) | .230 (5.8) | Black | Rubber | 500 | 4 | |

| EBBF-05-02-518-CL | .810 (20.6) | .300 (7.6) | Clear | Acrylic | 294 | 4 | |

| EBBF-05-02-518-BK | .810 (20.6) | .300 (7.6) | Black | Rubber | 294 | 4 | |

| NOTES |

| 1 - COLOR: OTHER COLORS AVAILABLE. INQUIRIES WELCOME (MINIMUM MAY APPLY) 2 - FOR OPTIMUM ADHESION SURFACE MUST BE CLEAN, DRY AND FREE OF GREASE AND DUST. ISOPROPYL ALCOHOL RECOMMENDED AS CLEANING AGENT. |

| MR-18 MATERIAL | |

| MATERIAL: | POLYURETHANE |

| HARDNESS, SHORE A.: | 60-70 |

| COLOR: | CLEAR AND/OR PIGMENTED. |

| UL RATING: | 94-HB |

| RoHS COMPLIANCE: | YES |

| TEMPERATURE RANGE (REF.): | -32° TO 120° F (0° to 50° C) |

| MR-44 RUBBER ADHESIVE | |

| ADHESIVE: | Rubber Base |

| THICKNESS: | .002" (0.05mm) |

| COLOR: | Clear |

| PEEL ADHESION: | 160 oz/in (1795 g/cm) PSTC 3, ASTM D3330 |

| STATIC SHEER TEST: | >300 Hrs. PSTC-07 Procedure A, ASTM B3645 |

| QUICK TACK STAINLESS STEEL: | 144 oz/in sq (633 g/cm sq.) |

| APPLICATION TEMP. RANGE (REF): | 65° to 100° F (18° to 37° C) |

| OPERATING TEMPERATURE RANGE: | 0° to 180° F (-18° to 82° C) |

| DWELL TIME (Before use): | 8 Hrs. Recommended |

| MR No: | 44. |

| MR-45 ACRYLIC ADHESIVE | |

| ADHESIVE: | Acrylic Base |

| THICKNESS: | .002" (0.05mm) |

| COLOR: | Clear |

| PEEL ADHESION: | PSTC-1, 7.2 ob/in. 15 minutes dwell |

| SHEER ADHESION: | PSTC-07 1/2"x1/2", 1000 grams, >10 Hrs. |

| TACK PROPERTIES: | PTSC-6, Rolling ball < 4 inches |

| APPLICATION TEMP. RANGE (REF): | 65° to 100° F (18° to 37° C) |

| OPERATING TEMPERATURE RANGE: | -40° to 200° F (-40° to 93° C) |

| DWELL TIME (Before use): | 24 Hrs. Recommended |

| MR No: | 45. |